Getting the most out of your fleet vehicles, and your day-to-day operations, requires focusing on several different factors; one of which is keeping up with preventive maintenance practices. Why? Because not only does it help keep your drivers safe, but it also extends the lifespan of your assets.

Without a proactive approach to fleet maintenance, you risk being in for costly downtime, and unscheduled repairs; not to mention, compromising compliance with safety standards and regulations.

To that end, a fleet maintenance routine makes sure that vehicle issues are detected and addressed on time. As a result, you’ll soon start saving money for your business; considering that regular upkeep costs less in the long haul — as opposed, of course, to a reactive maintenance approach.

3 preventive maintenance practices, to keep your fleet in peak condition

1. Have a consistent fleet maintenance schedule in place

Following a routine maintenance schedule is among the best practices in the fleet industry; in regards to both vehicle uptime, and driver safety. Of course, you should avoid waiting for a breakdown to happen before you bring a fleet vehicle to the mechanic. Otherwise, you not only put your drivers’ wellbeing at risk, but also your relations with your customers; along with your company’s reputation. Truth be told, unexpected breakdowns and downtime can cost your business, in many respects.

Naturally, a routine vehicle upkeep plan includes various preventive maintenance practices that are essential for steering clear of vehicle problems. The first thing you can do, towards that goal, is consult the manufacturer’s manual for recommended maintenance; as well as the OEM’s instructions, on parts and equipment care.

Then, you can start scheduling for maintenance, factoring in mileage, and driving hours per vehicle; maybe, including other factors too, such as fuel usage, vehicle age, or historical data on vehicle repairs, etc. Last, but not least, you should make a habit of performing maintenance consistently, and on regular intervals.

2. Delegate your drivers to perform regular vehicle inspections

While following a routine maintenance schedule can guarantee vehicle uptime (to a certain degree), sometimes, issues may arise ahead of schedule. Therefore, alongside your schedule, you should also assign your drivers to inspect vehicles, regularly. After all, they know them better than anyone.

However, before this assignment, make sure to thoroughly train your drivers in conducting vehicle inspections and identifying possible issues; that is, before they arise. Apart from this, you should also stress the importance of compliant and conscientious driving behavior. Some driver safety courses can help your drivers develop safe driving behaviors, and even become more productive, along the way.

All in all, implementing routine inspections into your preventive maintenance practices is key for an efficient fleet maintenance strategy; as they can provide you with in-depth insights into your fleet’s overall health.

3. Utilize vehicle monitoring software, for data-driven maintenance decisions

The good news is that, today, Telematics tools and technology offer an effective solution to help you keep repairs under control. Using a good fleet monitoring system, for instance, you can run vehicle diagnostics on-demand, from your office; and, even receive notifications about malfunctions, in real-time.

On top of that, you can monitor your crew’s driving patterns, and address dangerous behaviors, promptly. In this manner, you get to protect both your drivers and vehicles against preventable harm; you also save your business money on poor driving-related expenses.

At the end of the day, managing fleet maintenance is easy, when your entire fleet’s data is available on a central platform. From there, you can use metrics to track the effectiveness of your preventive maintenance practices and manage your maintenance schedule; and, of course, make adjustments whenever necessary, as well.

By streamlining your fleet’s preventive maintenance, you make sure that downtime and unnecessary expenses are a thing of the past.

Streamline preventive fleet maintenance with Veturilo!

Without fleet maintenance management software, it can be hard — if not impossible — to keep pace with a balanced preventive maintenance approach. Making the most of real-time vehicle diagnostics and driver scorecards — along with the preventative maintenance practices we mentioned earlier — can help you minimize both vehicle downtime and maintenance costs.

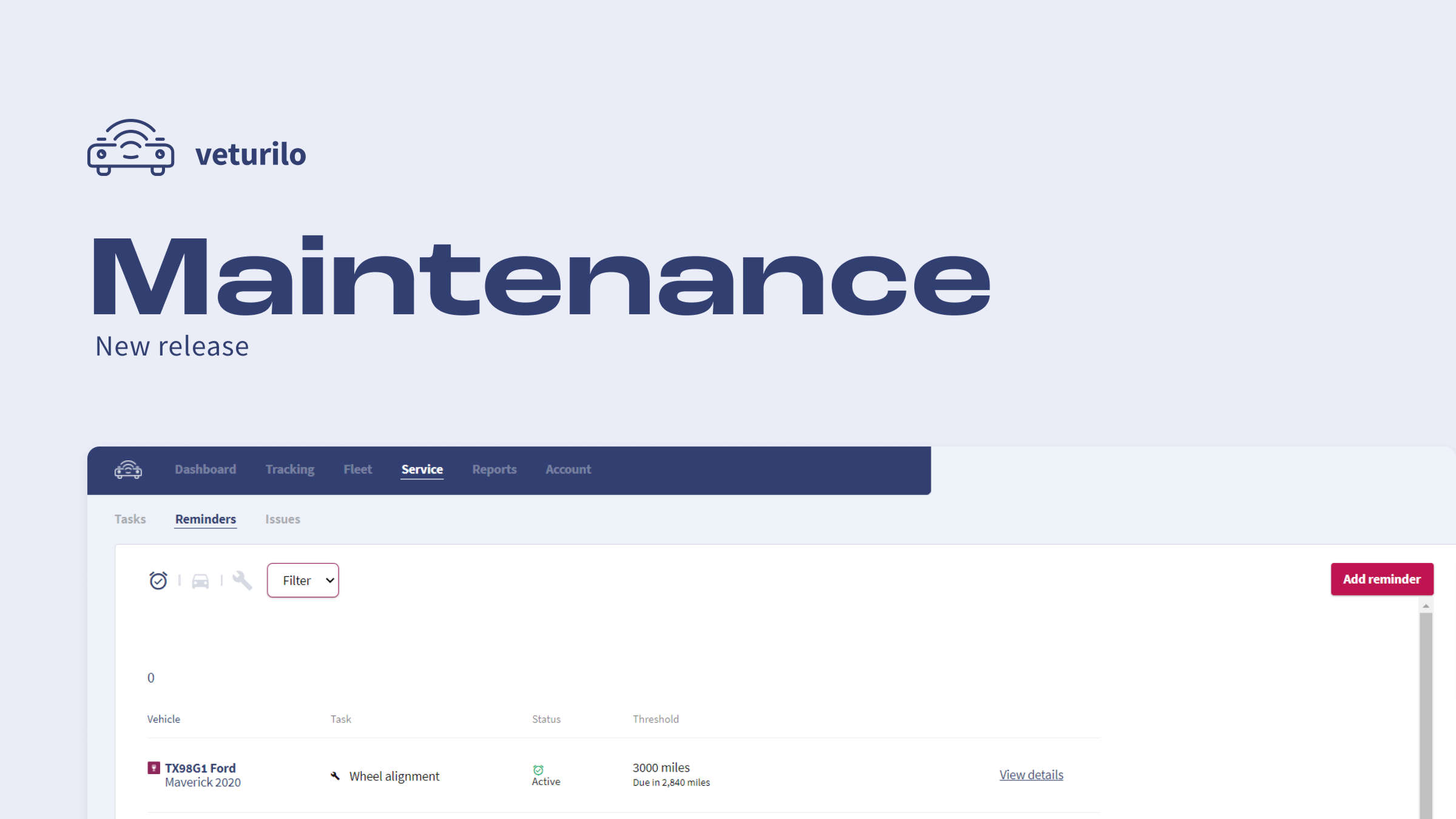

Below, we highlight three practical ways you can streamline preventive maintenance for your fleet, using Veturilo:

1. Keep your fleet assets healthy and robust, with vehicle diagnostics

You proactively address vehicle issues, such as low fuel levels, battery problems, or engine faults; through the diagnostics feature and the codes it provides. This way, you quickly identify vehicles in need of repair and, thus, avoid breakdowns. By extension, you protect the health of your fleet vehicles, and extend their lifespan.

2. Respond to maintenance issues promptly, with real-time alerts

With Veturilo, you receive real-time alerts regarding vehicle problems on your dashboard, ensuring that your drivers attend to them on the spot; or get the vehicle to an auto repair shop, informing the mechanic of the detected faults. On this account, you reduce downtime, and strengthen your daily operations.

3. Ensure your assets are operated safely, with driver behavior monitoring

It’s not a rare occurrence in fleets for unsolicited driving patterns to be the cause behind unwarranted vehicle wear and tear; thus, unexpected maintenance. Some examples of such driving behaviors include:

- speeding,

- fast acceleration,

- sharp turns,

- hard braking, and

- driving at a higher RPM than needed

Through Veturilo driver scorecards, you can keep an eye on your drivers’ behavior; with the purpose to ensure your vehicles’ are operated well, and are kept in good condition. At the same time, you can prevent speeding tickets, excessive idling time and even fuel fraud.